PIE-550: Plane Inspection Equipment

PIE-550 is a Surface Inspection System (WEB Inspection System) to detect any defects of a variety of web materials such as metal foils, sheet steel, paper and unwoven for sheet inspection, and glass, laminate plates, resin and food for individual sample inspection. It performs high precise inspection and user-friendly operation with Ikegami unique image processing technology.

Object:

Films, glasses, metal foils, laminate plates, resin, sheet steel, paper, unwoven, rubber and food

Defect type:

Contaminants, scratches, dirt, stains, uneven, wrinkles, streak, bubbles and pin hall

Features- Fail

Judgement - Display

Recording - Simulation

Function

Others- Rating

Performance - Download

- Contact

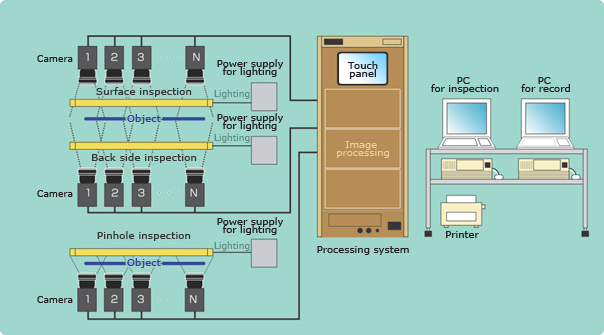

System Configuration

System ConfigurationIkegami unique image processing

| Ikegami unique image processing

|

Ikegami unique image processing

| Defect

|

Algorithm

|

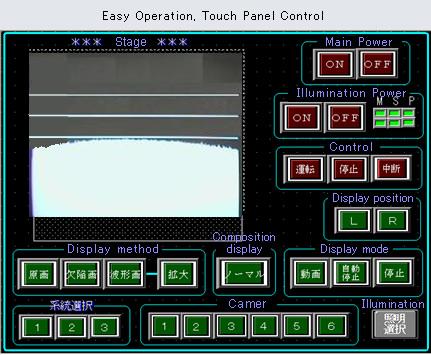

Touch Panel Control

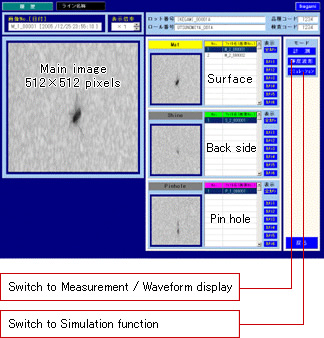

Fail images can be saved and displayed in real time (512x512 pixels) Each stage of fail image can be displayed in parallel.

|

(1) Main Power: ON/OFF (2) Illumination Power: ON/OFF (3) Control: Start/Stop/Interruption (4) Display position: L/R (5) Display method: Original/Defect image/Waveform (6) Composition display: Normal / Composition (7) Display mode: Movie / auto stop / manual stop (8) Stage (9) Camera (10) Illumination |

Fail images can be saved and displayed in real time (512x512 pixels) Each stage of fail image can be displayed in parallel.

|

- Main image display - Each stage image display Ex. Surface, Back side and Pin hole image are displayed in parallel - Switchable even under the inspection procedure |

Simulation function

Measurement display

|

The recorded image which shows target defects should be loaded. ↓ Set the parameter for the simulation. ↓ Set the detection algorithm for the simulation. ↓ The simulation result can be seen. ↓ You can judge the set parameter and algorithm are suitable to detect target defects. When the simulation result suits to detect the defects, the parameter and algorithm can be reflect on the settings of the system. If not satisfied, you can try the simulation on the PC with different parameter and algorithm. |

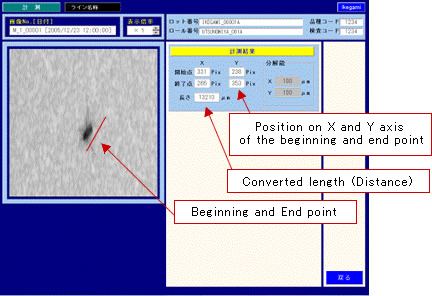

Measurement display

|

Clicking Beginning and End point for a target line (Indicated by a red line) ↓ Length information converted by the resolution |

Management PC, Recording PC

LANE display

|

■ Management PC

- Display setting - Printing setting - Others ■ Recording PC - Image display even under the inspection process - Simulation - Waveform / Measurement display mode |

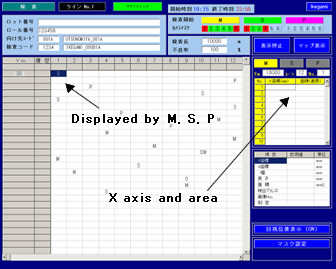

LANE display

| Position information of defects at each stage can be displayed in real time

■ Details information (1) X axis (2) Y axis (3) Width (4) Length (5) Area (6) Detection algorithm (7) Image No. (8) Judgement (PASS/FAIL) |

| Camera | CCD line sensor camera (40MHz) Selectable between 2048, 5150 and 7450 pixels |

|---|---|

| Lighting | Selectable among high frequency fluorescence light, halogen lamp, metal halide lamp and etc. |

| Image processing | 10 kinds of algorithm to detect defects |

| Operation System | Exclusive PC (OS: WindowsXP) LCD display,Printer |

| Mounting | For cameras and lighting |

- In case of emergency, please fill it in the message field.

- This page is encrypted using SSL before transmission.

- Ikegami shall properly handle personal information in accordance with the privacy policy posted on our website.

- For additional information shall refer to "Privacy Statements" on our website.

- Please fill-out all fields for sign up, click "Confirm" button.

- Preffered to fill in English.

-

In case, if you are accessing from European Union (EU) countries, please use Ikegami Europe official site, contact form to comply with the EU General Data Protection Regulation (GDPR). [Contact form: http://www.ikegami.de/contact.html]

In case, if you are accessing from European Union (EU) countries, please use Ikegami Europe official site, contact form to comply with the EU General Data Protection Regulation (GDPR). [Contact form: http://www.ikegami.de/contact.html]