POIE-8000C

Color Powdered/Granulated Medicine Inspection Equipment

Discontinued Product

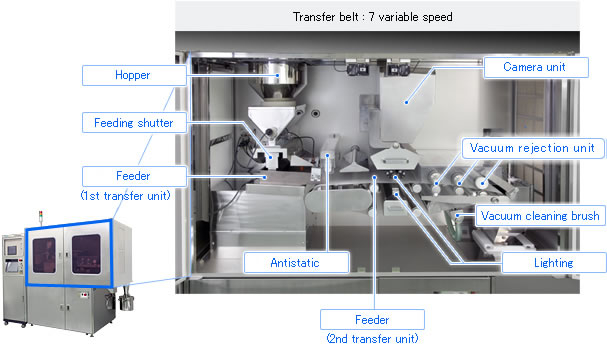

The POIE-8000C Color Powdered/Granulated Medicine Inspection Device combines the color processing technology developed for tablet inspection equipment with technology for screening powdered and granulated medicines for impurities, thereby boosting the precision with which colored foreign matter can be detected. This new device also allows for certain colors to be specified for the detection of foreign matter that color. The device also comes equipped with a “linear feature extraction processing function”, which facilitates the high-precision detection of fine fibers and hairs.With this new equipment, too, comes a marked increase in processing capacity thanks to the wide inspection conveyor belt that provides a stable, constant supply of sample material and the five-speed conveyor belt action (top speed is approximately 18m/minute).

In addition, the exclusion mechanism employs a reliable rotary nozzle system. This ensures that accurate pinpoint suction is provided only around the foreign substance, thereby boosting the recovery ratio of quality product.

*Processing capacity: More than double (based on in-house comparisons)

*This product was jointly developed in conjunction with Eisai Co., Ltd.

High Speed Inspection: Max. Output 200kg/h

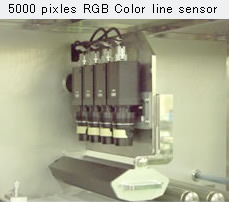

Camera Process System: 5000 pixles RGB Color line sensor / 20μm resolution

Inspection accuracy:

Black/Dark foreign material larger than Φ40~60μm

Black/Dark fiber larger than Φ30μm×3mm

Detect fiber/hair/foreign material

Fiber/Hair

Line distinction processing to detect

Black/Dark color foreign material

Color processing for specific color detection

Type of foreign material : Color foreign material ; Hair, Metal, Carbide and fiber

Color processing

Color calculation feature:

High brightness/luminosity color detection is difficult with light and shade difference processing

Distinction extraction with color processing

RBG full color processing ? accurate detection of color foreign material

Specific color detection

Easily influenced by shades of granules

Fiber lighting for uniform and high intensity illumination

- Random arrangement fiber for uniform illumination

- Higher than 100,000- lx intensity

- Automatic lighting adjustment flexible for change of inspection circumstance

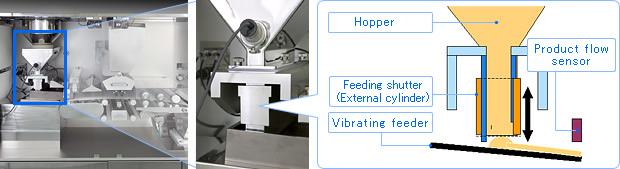

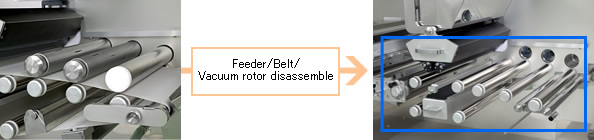

Feeding shutter for constant feed

Stable and constant feeding with 2nd transfer unit

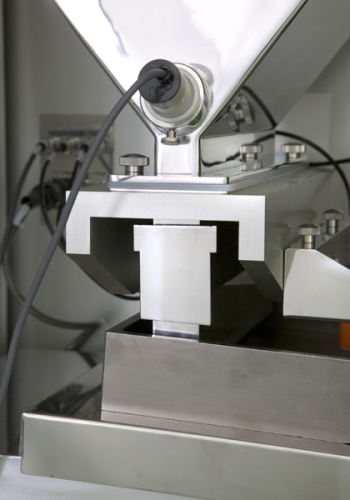

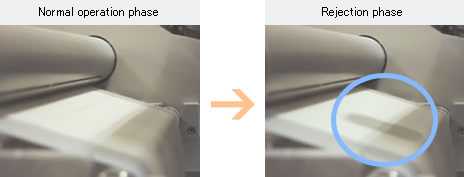

Spot vacuum with rotary nozzle system

Spot vacuum with rotary nozzle

Correct rejection control

Correct rejection control

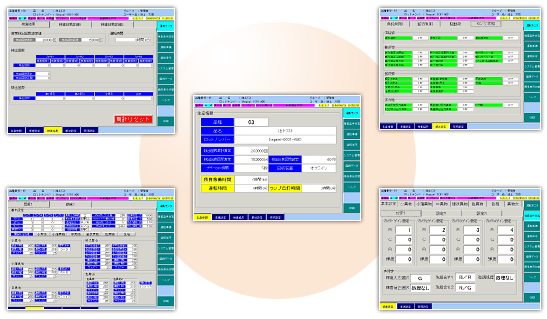

Easy operation with touch panel

Optional Functions

| Access security 3 levels with ID and password Administrator/Supervisor/Operator |

Display function Inspection input image/Detection image/waveform |

| Detection data memory Last 16 images memory Image data transfer to extended PC |

Operation monitoring function Transfer unit / Rejection unit / Processing unit - Selfdiagnostics |

| Measuring function measuring function for memory data |

System log Log for machine status and critical changes |

| Data input/output function Display for production data, parameters and result report Batch report printout |

Automatic lighting adjustment function Automatic lighting adjustment to set point |

Detection image memory

- Store detection image

Store max.6,400 last detection images

(64image×100set)

(64image×100set)

Measure length of foreign material in 512×512 pixles - Measure distance between 2 points

- Magnifying display

5 times magnifying display - Play data in PC

Play the stores image in Windows PC

| Applicable Particle | Powder, Fine Granule, Granule etc., Colored |

| Inspection Throughput | 20 - 100 kg / hour |

| Inspection Objects | Black or Colored Foreign Particle of over 40 - 60μm (diameter), Black or Colored Fiber and Hair of over 30μm (diameter) x 3mm * Inspection accuracy depends on inspection throughput and object. |

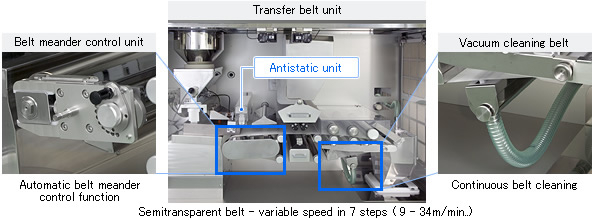

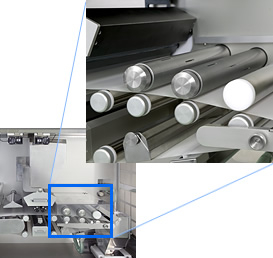

| Transport Section | Transport belt: 1 row Transport Belt speed: Approx. 9 - 18m / minute (5 steps selectable) Inspection area: Approx. 392mm in width Transported particle thickness: Approx. 0.3 - 0.7mm (1 layer) |

| Camera Section | 5,000 pixel RGB CCD line sensor camera x 4 units Limit of resolution: 20μm |

| Lighting Section | Lighting system: Fiber guide Lighting source: Halogen lamp x 12 Lighting position: 2 spots at top, 1 spot at bottom Lamp system: DC lighting system (lighting level variable at 16 steps) Lighting control: Manual / Auto control selectable Expected lamp life: 1,000 - 1,500 hours |

| Power Source | Power supply: Three phase 200V ± 10%, 50/60Hz Power consumption: 5kVA or less Connection: Terminal fixed with 6mm-screw |

| Air | Pressured Air Pressure: 0.5Mpa or more Consumption: 0.7NL / minute or less (clean dry air) Coupling socket size: Quick-connect air coupler socket 20SH |

| External Dimensions | Control unit: W570 x H1850 x D710mm Main unit : W1708 x H2050 x D1149mm Air-vacuuming unit: W750 x H1333 x D532mm |

| Weight | Main unit: Approx. 1,000kg (2,203 lbs) Control unit: Approx. 150kg (330 lbs) |

| Environment Condition | Temperature: 15 - 20 ° C (59 - 77 ° F) Humidity: 30~60% |

| Vacuumed Air Exhaust | Negative pressure: 4Kpa or more Exhaust air emission: 10 cubic meter / minute |

- Personal information is required

- Software

To download these information, personal information is required. Click the right blue button to download. :Personal information is not required.