PIE-650M

Single Sheet Visual Inspection System

PIE-650M is a Single Sheet Visual Inspection System with the high speed scanning cameras (max. data rate: 850MHz) to detect any defects of a variety of single sheet such as metal foils, sheet steel, paper, unwoven, glass, laminate plates, resin, food and liquid crystal display. It performs the high precise inspection and user-friendly operation with Ikegami unique image processing technology.

Detecting defects with high-speed and high-definition helps to improve production quality.

The system can be flexibly configured between small-scale and large-scale system depending on customer’s demands.

Main Features

- Detecting a variety of defects with multiple lighting systems such as reflective and trans illumination.

- Multiple defects can be detected with one set of camera. This system can improve the efficiency of inspection.

- Min. defect size: 50 μm, Max. transfer speed: 100 m/min.

- User friendly operation (touch panel)

- Flexible customization (installation space, GUI), additional defects can be registered by arranging lighting system.

- Easy maintenance.

- Over 40 years of experience of inspection.

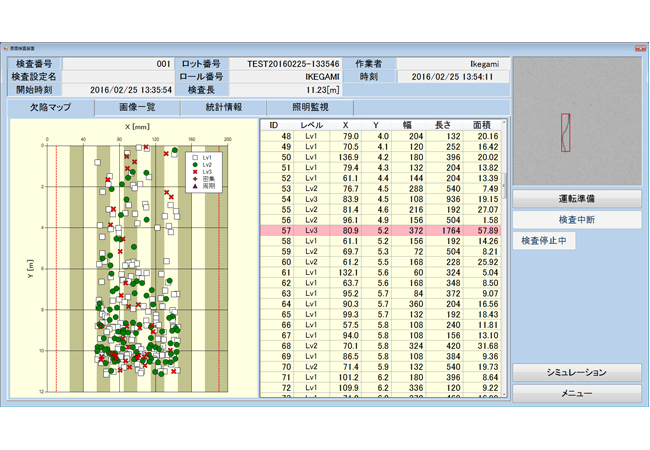

Failed Object Display

- Real-time display

Failed/defective objects can be displayed on screen in real-time. - Mapping display

Multiple objects can be displayed as a map, and each object can be switched for individual image view.

Object Images Listing Feature

- All images can be listed on display with the inspected data.

Even during the inspection, the simulated result report can be viewed.

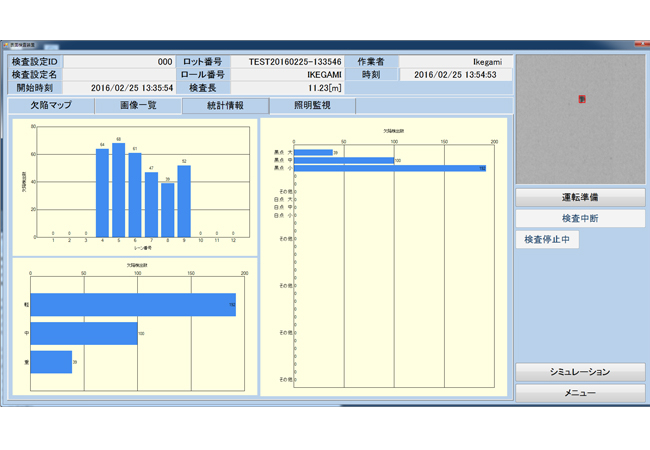

Statistical Data Display

- Statistical data can be displayed as graphs and number.

Inspection result can be displayed as statistical data visually for understanding and analysis.

| Camera | Line sensor camera (6,000 - 16,000 pixels, 160 MHz - 850 MHz) |

|---|---|

| Lighting | Line-type LED etc. |

| Image Processing | 11 kinds of algorithm to detect defects, Maximum 200 defect types classification, defect-level, cycle / cluster level |

| Functions | Simulation, Defect mapping, Statics information viewing, Inspection history viewing, Waveform monitoring, Speed tracking, System log recording, etc. |

| Available objects | Films, Glasses, Metal foils, Laminate plates, Resin, Sheet steel, Unwoven, Rubber and Food, etc. |

| Detectable defects | Scratch, Dingy, Wrinkles, Uneven, Foreign matters, Unwanted lines, Streaks, Pin holes. |

| Weight | Depends on the system. |

| External Dimension | Depends on the system. |

| Power Source | Depends on the system. |

| Operate Environment | Temperature:10℃ to 35℃, Humidity:20% to 80%RH (Condensation must be avoided) |

| Option | External input/output control, Marking machine, Remote monitoring, Branching operation display, Offline verification application (checking log/defect simulation), CSV, etc. |

- Personal information is required

- Software

To download these information, personal information is required. Click the right blue button to download. :Personal information is not required.