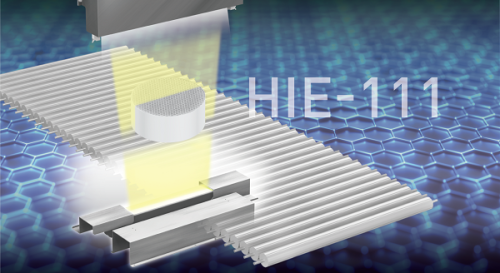

HIE-111

Honeycomb structure visual inspection system

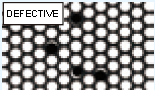

Cell plugging of the porous honeycomb structure can be inspected automatically by this vision system for the production quality control, counting the cell number and measuring the cell size.

High resolution image acquisition

High performance line sensor cameras are employed and they can contribute higher precise inspection minimizing the lens aberration for the widely required field of view.

Optimized illumination

The optimized illumination is designed for the size, color and material of the inspection objects.

User friendly operation

Touch panel operation can lead the operators for the easy settings and inspection procedure.

Inspection Result

The inspection sensitivity settings can be set according to the products.

Static Information

Inspection results can be viewed with the graphs and numbers, and the images can be recorded and displayed.

Simulation view

Inspection simulation can be available with the saved defect data.

| Objects Porous | honeycomb structure |

|---|---|

| Camera | Line sensor camera |

| Lighting | Line-type LED etc |

| Object size | Width 400mm, Length 400mm or phai 400mm |

| Performance | Minimum phai 1mm cell |

| Tact time Minimum | 5 seconds (at phai 150mm size of object) |

| Functions | Cell plugging detection, Cell number counting, Cell size measurement, Static information viewing, Image recording, Simulation, Inspection history viewing, Speed tracking, System log recording, etc. |

| Loading speed | 200mm / sec to 500mm / sec. |

| Operation temperature | 10℃ to 35℃ |

| Operation humidity | 20% to 80%RH (Condensation must be avoided) |

| Options | External input/output control, Marking machine, Loading machine, Remote monitoring. |

*The power consumption, outline and weight should vary according to the system configuration and designing.

- Personal information is required

- Software

To download these information, personal information is required. Click the right blue button to download. :Personal information is not required.