TIE-10000

Tablet Inspection Equipment

Ikegami's new tablet inspection system "TIE-10000" realizes high-speed processing of up to 700,000 tablets per hour. TIE-10000 detects various defects with high accuracy, and contributes to the efficiency and quality improvement of the inspection process.

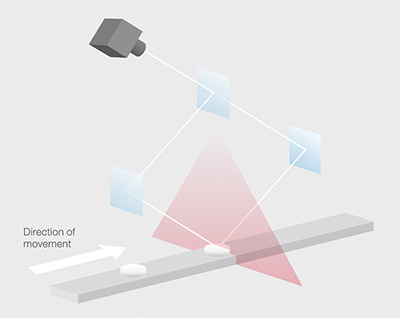

Fusion of newly developed optical system and image processing technology

High-precision all-around inspection

In the standard inspection section, a newly developed optical system enables the color area sensor camera to capture 5 viewpoints on one side and 10 viewpoints on both sides, realizing highly accurate all-around inspection without any blind spots. By capturing images of the sides from an angle, the accuracy of defect detection near the edges has been dramatically improved.

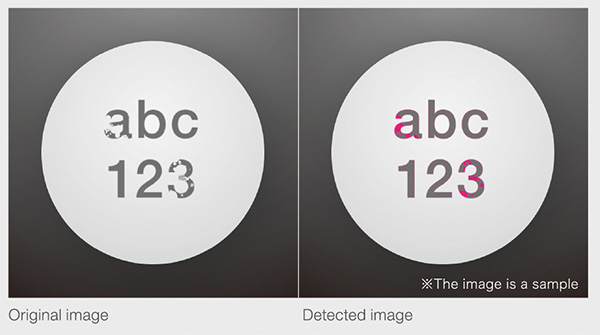

Pattern matching process

Pattern matching process improves the inspection accuracy of characters with printing defects, etc.

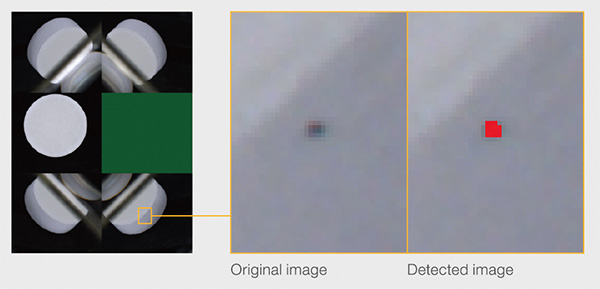

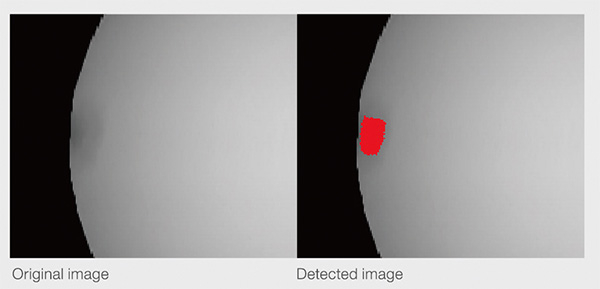

Optical composite 3D image

Chipping and cracking defects can be detected with high accuracy by combining the optical cutting method and Ikegami's original optical composite 3D image method.

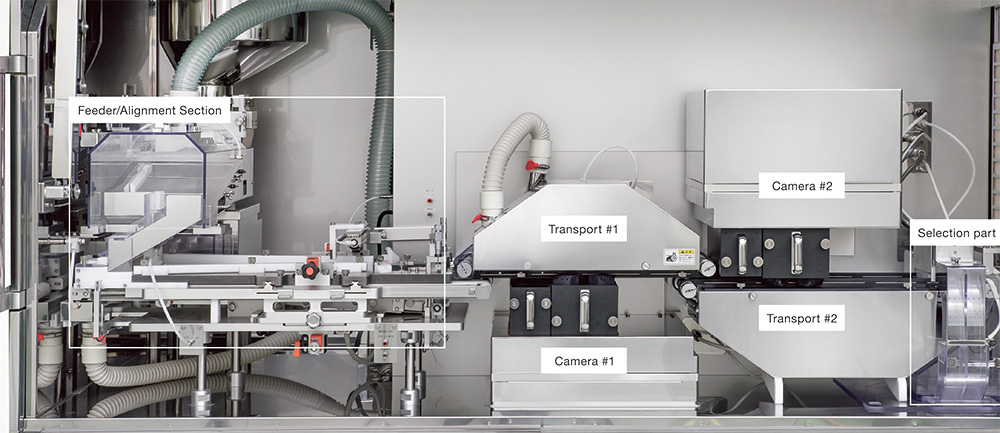

Feeder and alignment section for stable tablet supply and 2-row horizontal transfer system enable processing of up to 700,000 tablets per hour*

* φ5mm Film-coated tablet

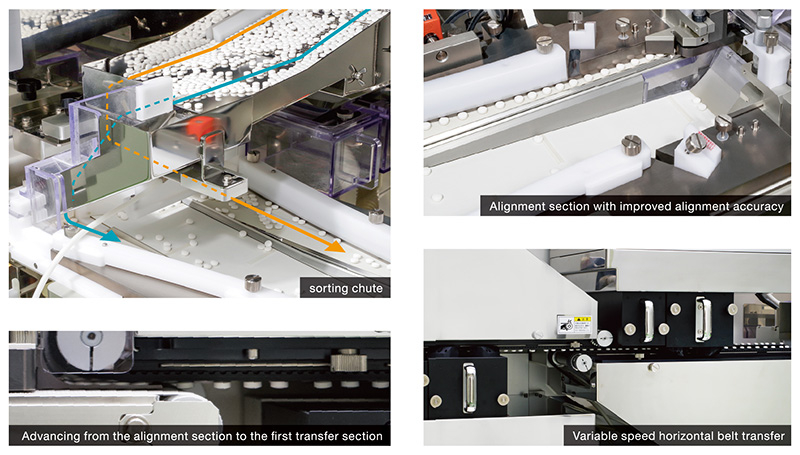

Feeder and alignment section with large capacity and stable supply

In the feeder and alignment section, a new unit with a sorting chute has been implemented, which stabilizes the tablet feeding amount to the alignment section and improves the filling rate and alignment accuracy. The tablet feeding amount to the inspection section has been increased, ensuring high faster processing.

Variable speed horizontal belt transfer

Maximum belt speed is 65 m/min. Variable transfer speed enables stable transfer according to the shape and characteristics of tablets.

Pursued operability and ease of operation and maintenance to reduce the burden of operators

Now with 24-inch touch panel

The large screen can display a large amount of information at once, reducing the number of times the screen is switched, allowing faster and easier operation.

Simulator function(Standerd)

The system can record images of up to 1000 tablets as a reference, and simulate defect detection and acceptance rate. Simulation makes it possible to apply the optimum inspection sensitivity for actual production.

Video support function

Video displays on the touch panel the procedures for disassembling and assembling parts at the time of product type switching to support the operation.

High visibility front door

The front and top surfaces of the door are transparent, allowing the operator to see what is going on inside during operation. In addition, the door is a flip-up type, which secures the operator's access line when the door is open.

Improved maintenance

The height of the transfer section has been lowered by about 150 mm compared to conventional models, allowing for easy disassembly, assembly, and cleaning of parts.

| Applicable tablet | Plain tablet, Film-coated tablet, Sugar-coated tablet, Irregular-shaped tablet |

| Applicable size | Round tablet:φ5 to 12mm, Thickness 2 to 8mm Irregular-shaped tablet:Wide 5 to 12mm, Length 5 to 21mm, Thickness 2to 8mm |

| Color | White color - Dark Brown, Colored type |

| Inspection items | Stain, Printing smudge, Chipping, Cracking, Deformation, Discoloration, Color difference, Hair, Fiber, etc. |

| Inspection accuracy | 50 micrometer in diameter or larger corresponding to black spot |

| Processing capacity | Maximum 700,000 tablets/hour *φ5mm Film-coated tablet |

| Lighting | Standard inspection:High & stable liminance LED 3D inspection:Laser slit light |

| Camera | Standard inspection:CMOS color area sensor camera 3D inspection:CMOS area sensor camera |

| Judgement process | High speed, real-time parallel processing / dedicated processor method |

| Power requirement | Supply power:AC200V±10% 3φ 50Hz/60Hz 8kW or higher Less than 8kW |

| Air supply | Pressure:0.5MPa or more Consumption:Approx. 600 liter per minute Connection caliber:High coupler socket (400SH - 400PM) |

| Operating temperature | +20°C to +30°C |

| Relative humidity | 30% to 70% (non-condensing) |

| External dimensions |

W1980 x H1750 x D1100mm (excluding protrusions) |

| Weight | Approx. 1800kg |

| Optional features | Congestion removal feature, CSV function, Deduster/Cyclone unit, Printing software, Shock-absorbing of tablet |

- Personal information is required

- Software

To download these information, personal information is required. Click the right blue button to download. :Personal information is not required.